| Step | Time elapsed |

Duration of step |

Climate settings at start of step |

Comments |

|||

| no | h | m | h | m | T(°C) | %RH | Comments |

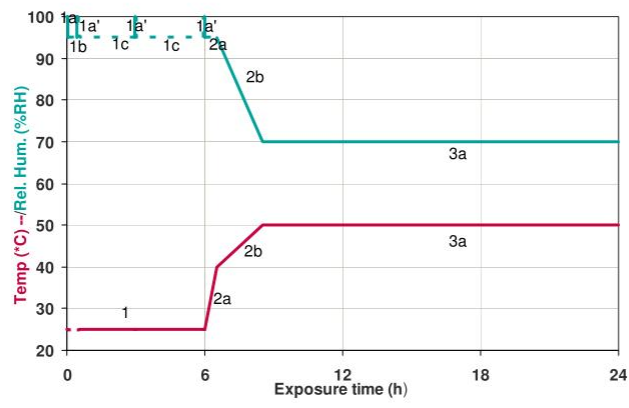

| la | 0 | 0 | 0 | 10* | 50* | 70* | Spray thoroughly 0.5% NaCl to wet and cool 0.5% 氯化钠,湿透且冷却 (此阶段开启喷淋,喷洒0.5% 盐水来实现湿润状态) |

| lb | 0 | 10 | 0 | 20 | 30-50 | wet | Cool chamber with maximum capacity 最大限度冷却试验箱 (此阶段以设备最大做功能能力来实现降温) |

| la’ | 0 | 30 | 0 | 3 | <30 | wet | Spray to regain wetness (cooling dries) 通过喷洒使干冷的试验箱再次湿润 (此阶段为第二次喷淋) |

| lc | 0 | 33 | 2 | 27 | <30 | wet(95) | 25±2 to be reached within 1 h from start (la) 从步骤 la 开始,一小时内达到 25±2从测试 (此阶段要设定目标温度,湿度95) |

| la’ | 3 | 0 | 0 | 3 | 25±2 | wet | Secure and support wetness by spraying 通过喷洒保持湿润 (此阶段为第三次喷淋) |

| lc’ | 3 | 3 | 2 | 54 | 25±2 | wet(95) | wet (95) = OK to set to 95% RH 湿度 (95)= 可以设置到 95%RH (此阶段已经稳定运行在温度25湿度95) |

| la’ | 5 | 57 | 0 | 3 | 25±2 | wet | Defines wet condition before climate control 环境控制前明确湿工况 (此阶段是第四次喷淋,也是最后一次喷淋过 程) |

| 2a | 6 | 0 | 0 | 30 | 25±2 | wet(95) | Start of quick temperature rise without drying 开始快速加温,但不能干燥 (此阶段再次将温度控制在25,湿度控制在95) |

| 2b | 6 | 30 | 2 | 00 | 40±0.6 | wet(95) | Start of slow drying by diffusion 通过扩散,开始缓慢干燥 (此阶段控制要求温湿度线性变化) |

| 3a | 8 | 30 | 15 | 30 | 50±0.6 | 70±3 | Panels shall be free from visible wetness 板上无可见水迹 (此阶段控制要求温湿度线性变化) |

| 3a | 24 | 00 | - | - | 50±0.6 | 70±3 | End of “workday” procedure “工作日”程序结束 (到此阶段,一天24小时的测试工作完成) |

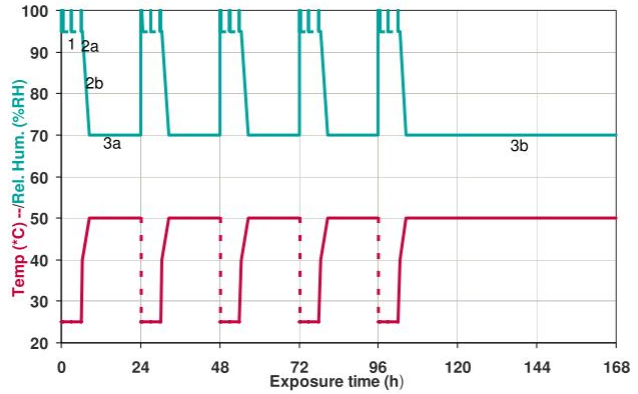

| Repeat steps | 1a - 3a another four times 步骤 la-3a 再電复 4 次 (到此阶段,总共完成5次循环,一周工作日五天的测试工作结束) |

||||||

| 3b 3b |

120 168 |

00 00 | 48 - |

00 - |

50±0.6 50±0.6 |

70±3 70±3 |

Phase in with weekends in case of manual operations in ”workday” procedure (此阶段在周末的二天内设备工况保持在温度50湿度70) |

| Repeat steps | 1a-3b for required number of weeks (到此阶段,一周七天的测试工作结束) | ||||||

| * Provided proceeding from step 3a or 3b |

|||||||

扫一扫,关注我们最新消息

扫一扫,关注我们最新消息 工作时间:周一至周五 9:00-18:00

联系人:钟经理

手机:13600292956

邮件:dgkedi@qq.com

地址:东莞市寮步镇泉塘工业区中星街3号